What are vinyl panels?

First of all, it should be noted that vinyl-covered floors not only look good but are also practical in terms of use. The wide range of applications is also important because this product works perfectly in every room, including those with a public character.

Interestingly, vinyl panels are not a new invention. PVC was incredibly popular in the 1980s and was present in many Polish homes in the form of linoleum. Today, it is a completely different material. Produced as panels or tiles, it stands out for its high quality and is available in various colors and patterns.

So, what are the benefits of vinyl flooring? It is primarily easy to install, impressively durable, easy to maintain, resistant to moisture, and visually attractive. In summary, it combines ergonomics and aesthetics.

- Vinyl panels and their functional benefits

- We assess the properties of the floor in relation to 3 classes:

- Wear resistance of vinyl floors

- Core of vinyl panels

- Which vinyl panels to choose - glued or floating?

- Vinyl panels and underfloor heating

- Vinyl panels and health issues

- Caring for vinyl floors

- Summary

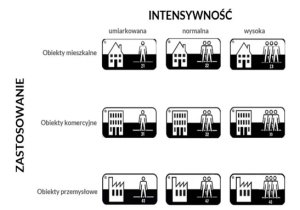

Regardless of whether we want to use laminated or floor coverings, the evaluation mainly depends on the same thing - the utility class, which takes into account not only the top layer of the panels but their entire construction. It is worth noting that in the case of vinyl floors, there is no classification related to wear resistance level.

Referring back to the utility class - to evaluate the panels we are buying, the pictograms placed on the product help:

- class 2 - this is the class of residential properties: class 21 is spaces with low to moderate traffic intensity (e.g. bedrooms); class 22 is spaces with normal, or average traffic intensity (e.g. living rooms); class 23, on the other hand, includes spaces with high traffic intensity (such as all communication routes in the house, such as corridors).

- class 3 - this is the class of commercial, public properties: classes 31, 32, 33, and 34 distinguish different levels of exposure to traffic; the higher the class, the higher the intensity of traffic. Class 31 includes rooms with low traffic intensity or those that are used relatively rarely (e.g. hotel rooms or conference rooms); class 32 includes spaces with moderate traffic intensity (e.g. small shops); class 33 covers areas of the building characterized by heavy traffic intensity (e.g. classrooms or corporate offices); whereas class 34 refers to intensively used facilities (e.g. shopping centers).

- class 4 - this is the class of industrial properties: the classification is analogous here. Class 41 refers to areas where work is mainly done in a seated position (e.g. workshops dealing with electronic solutions production); class 42 includes areas characterized by standing work and light vehicle movement; class 43 is areas where light industry operates, generating very intense use.

The choice of wear resistance class of panels determines the nature of the space in which they will be used. In apartments and houses, a thickness of 0.30-0.40 mm is usually sufficient. A thicker wear layer is recommended for public and industrial buildings, with a thickness of 0.55-7 mm, which directly translates into the durability of the floor. It is worth noting that this type of panel, although dedicated to intensively used spaces, can also be installed in homes.

The wear layer of vinyl coverings is not the only aspect that affects the quality and price of this product. The core, which is not visible to us but extremely important for the durability of the entire product, is also crucial.

Below are the types of cores available on the market:

- Flexible LVT panels are the first type of panels that appeared on the market. Known primarily for their high flexibility, they are built with many layers of vinyl. Their core sometimes contains layers of fiberglass, which contribute to better stability. The top layer provides protection against wear, allowing these products to be used in public utility buildings. Additionally, they are waterproof, compatible with underfloor heating, and stand out for their very nice imitation of natural wood beauty, thanks to the quality foil and high-resolution printing. A downside of these panels? PVC, from which they are constructed, is highly thermoplastic, which means that the material's flexibility and volume can change, leading to deformation, bulging, or even unlocking of the panels in the face of sudden temperature changes or high sunlight exposure.

- EPC - Extruded Polymer Core, the core present in the latest generation of vinyl panels, is made of foamed material and consists of only one layer, which gives the product impressive rigidity and increases its thermal stability. However, the foaming, which can be simplified to mixing with air, results in less material consumption, and the panel itself is lighter. A downside? The EPC core conducts heat worse, and its low density means that a potential object falling on the floor may leave a visible dent on it.

- SPC - Solid Polymer Core, the core that is highly dense and consists of a mixture of plastics and other materials. This is the most modern technology currently on the market, making the panels both waterproof and dimensionally stable, perfectly suited for underfloor heating.

There is not just one form of vinyl panels. There are several options. The most popular are vinyl sheets, glued vinyl panels, and those installed with a click-lock system. Each of the mentioned floors is waterproof, but each of them also has its specific advantages and disadvantages. The final choice is influenced by several specific factors.

- SUBFLOOR - Glued vinyl floors, as the name suggests, require the use of adhesive during installation, which attaches them to the subfloor. On the other hand, click-lock vinyl panels are installed differently. In this case, you can count on excellent connection and floor protection. There are many supporters of both solutions, so it is worth gathering some basic information, especially relevant when making a purchase decision. One of these is, for example, the requirements for the subfloor. If the subfloor is exposed to high humidity (such as underground concrete), it is better to choose click-lock panels and install them with a protective layer. Glued vinyl panels are usually thinner, which means they provide less insulation against all hard surfaces. In conclusion, if you want to feel the pleasant softness underfoot, it is worth choosing click-lock panels. At the same time, it is important to be aware that any vinyl floor can be installed on various subfloors. The only condition is that their condition must be good.

- ROOM SIZE - When considering which type of panels to use, it is important to take into account the size of the room. The larger the space, the less stable the connections are in the case of a click-lock floor. The recommended solution in such cases is a glued floor, which does not require the use of expansion joints. It will work, for example, in gastronomic premises or cellars. Both types of panels can be used in spaces like kitchens, bathrooms, and some commercial areas.

- INSTALLATION - If you want to install the panels yourself, have no experience in this area, and want the process to be simple, fast, and uncomplicated, you should choose click installation floors. In this case, not only glue but also a number of additional tools are unnecessary. The decision to buy glued panels should be accompanied by the commitment to work with a specialist who has experience in their installation and will ensure optimal results. Although it may be a higher initial cost, in the end, it saves time, effort, and money needed for any corrections or replacements of the product.

- BUDGET - Developing the thread started above, it is worth analyzing the costs. Although glued panels are usually cheaper, click-lock panels can be purchased in various thicknesses and with an integrated underlayment, which ultimately provides many additional benefits.

Underfloor heating is an increasingly popular solution in apartments, houses, as well as public and commercial spaces. It is a comfort that more and more people are reaching for, wanting the entire space of the room to become a carrier of evenly and optimally distributed heat. Keeping this in mind, it should be emphasized that vinyl panels work perfectly with underfloor heating. Why is this so? This type of product is thinner than wood, which means it conducts heat better and faster and has low thermal resistance. Regardless of the type of panels chosen, it is necessary to adhere to the manufacturer's recommendations, which specify the highest acceptable temperatures for this material.

There is an unjustified and unconfirmed opinion that PVC, the polyvinyl chloride discussed here, is harmful to health and not environmentally friendly. It must be clearly stated that this opinion has nothing to do with reality, and the fact is that all building and construction products, including those used in residential interiors, must undergo many rigorous tests before being allowed on the market.

It is also worth emphasizing that although chemical substances are used in the production of vinyl panels - similar to wooden and glued planks - the PVC used in this process is hardened, resulting in the high durability of the product. Furthermore, vinyl floors are recommended for people with allergies and asthma because their antistatic coating repels dust and keeps the home environment clean.

Cleanliness matters everywhere! In private, office, and commercial spaces. Considering this aspect, it is recommended to use vinyl panels. They are incredibly easy to clean, resistant to dirt and stains. The protective coatings used on their surface make the floor cleaning process quick and easy, with few necessary cleaning agents. However, it is important to remember that the effectiveness of the coating depends on the manufacturer, and there are many of them.

What should definitely not be done? In the context of vinyl panels, bleaches or strong detergents dedicated to household cleaning are not suitable. Their action can damage the floor by affecting the protective top layer of the product. However, the advantage of vinyl panels is that even in this case, there is a solution - simply use a special repair product to easily remove local scratches.

Practical, aesthetic, and budget considerations - all of these speak in favor of installing vinyl panels, which can be used in any room, regardless of its character, size, or intensity of use.

The key to the perfect floor that will last for years is a good choice, and this can be done by the experts at PARKIET STUDIO. We invite you!